Turbochargers are an essential part of many modern trucks, providing more power and efficiency by forcing extra air into the engine. This boosts performance and enhances fuel economy, which is why turbocharged trucks are popular among truck owners. However, turbochargers are prone to wear and tear, especially when used heavily. If a turbocharger fails, it can significantly affect your truck's performance. But how do you know when something’s going wrong with the turbo? Recognizing the early signs of a failing turbocharger can save you from expensive repairs and downtime.

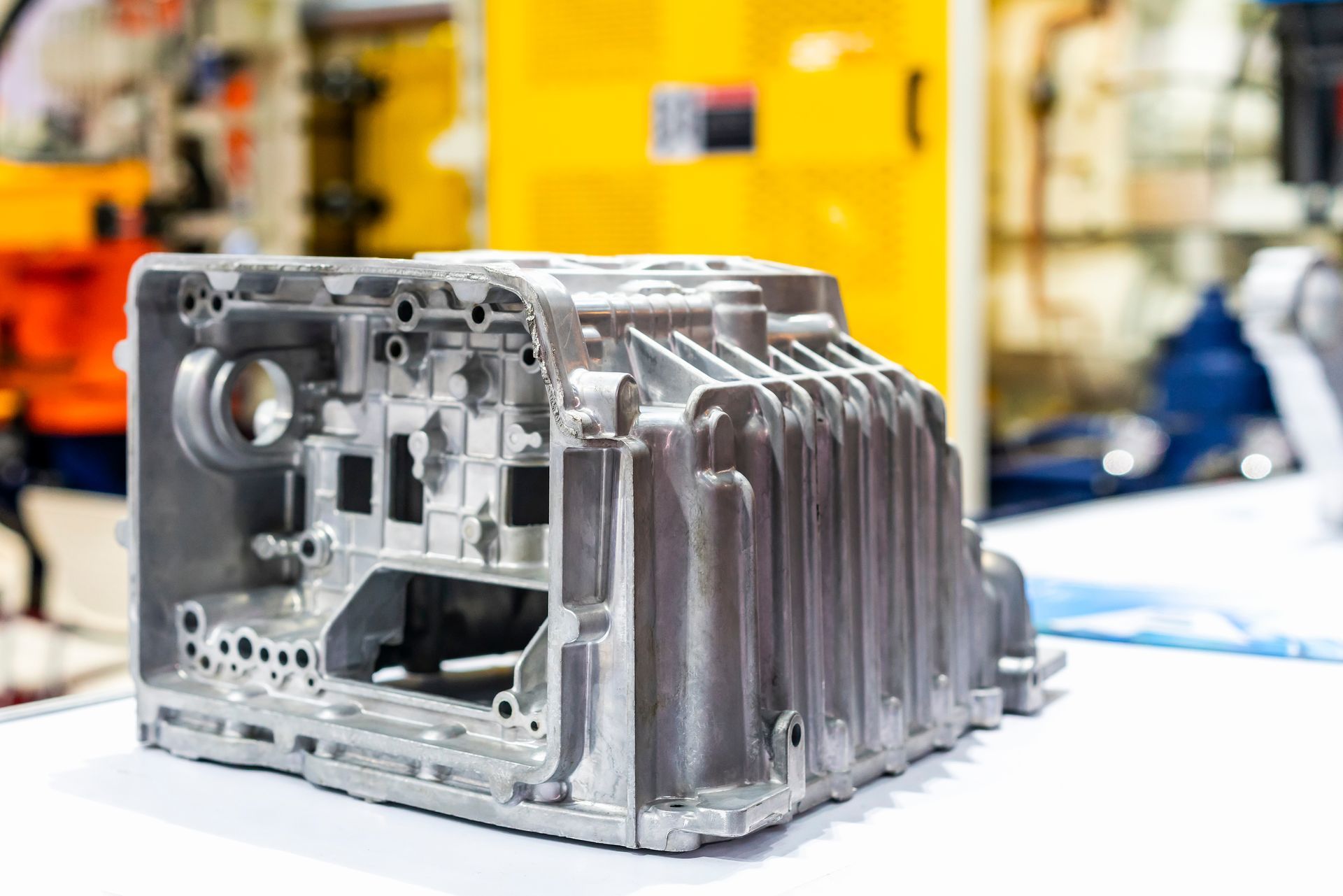

1. What Is a Turbocharger and How Does It Work?

A turbocharger works by compressing the air entering the engine, allowing the engine to burn more fuel and produce more power. It uses the exhaust gasses from the engine to spin a turbine, which forces more air into the combustion chamber. The result is a powerful boost in performance and efficiency without increasing engine size.

Over time, the turbo's components can wear out due to high heat, pressure, or oil problems, eventually leading to failure. Identifying the warning signs early on can help you avoid a complete breakdown.

2. Common Signs of a Failing Turbocharger

Loss of Power

If you notice that your truck doesn’t have the same acceleration or power when you press the gas pedal, this could be a sign of a failing turbo. Since the turbocharger provides extra power by compressing air, a drop in power could mean it’s not functioning as efficiently.

Excessive Smoke from the Exhaust

A well-functioning turbocharger helps maintain a clean burn of fuel. However, if the turbo is failing, you may notice excessive smoke coming from your truck’s exhaust. The color of the smoke can vary, but black, blue, or white smoke often indicates an issue. Blue or white smoke can signal that oil is leaking into the turbo, while black smoke suggests that the engine is burning too much fuel.

Whining or Squealing Noise

Turbochargers can make noise, but if you hear a loud whining or high-pitched squealing sound that wasn't there before, this could be a sign of trouble. A failing turbo can produce unusual noises as its internal components, such as the turbine or compressor, start to wear out or become unbalanced.

Check Engine Light

While the check engine light can come on for various reasons, it’s worth paying attention to if you're also experiencing some of the other symptoms on this list. A failing turbocharger might trigger the light due to performance issues or increased exhaust emissions. It’s always a good idea to have your truck inspected if the check engine light is on.

Poor Fuel Economy

One of the benefits of a turbocharger is its ability to improve fuel efficiency. If you notice a sudden drop in fuel economy, it could be due to a failing turbocharger. As the turbo fails, it won't be able to compress as much air into the engine, leading to a less efficient combustion process.

3. Causes of Turbocharger Failure

Oil Contamination

Turbochargers rely on a steady supply of clean oil to function properly. If the oil becomes contaminated with dirt, debris, or other contaminants, it can damage the turbo's moving parts, leading to premature failure. Regular oil changes are essential to preventing this issue.

Excessive Heat

Turbochargers operate under high temperatures. If the turbo is overworked, such as during heavy towing or driving at high speeds for prolonged periods, it can overheat. Excessive heat can cause the internal components to warp, leading to a failure.

Wear and Tear

Like any mechanical part, turbochargers will wear out over time, especially if the truck is frequently used for heavy-duty tasks. Regular inspections can help identify wear and tear before it leads to complete failure.

4. How to Maintain Your Turbocharger for Longevity

While turbochargers can wear out, proper maintenance can help extend their lifespan and keep your truck running efficiently. Here are a few tips to maintain your turbocharger:

Change Your Oil Regularly

One of the simplest yet most effective ways to maintain your turbocharger is to keep up with regular oil changes. Clean oil ensures that the turbo’s components are properly lubricated and free from contaminants.

Let Your Engine Cool Down

After a long or hard drive, give your engine some time to cool down before shutting it off. This allows the turbocharger to slow down and cool properly, reducing the risk of damage from heat.

Use Quality Fuel and Oil

Cheap or poor-quality fuel can cause deposits to form on the turbocharger, leading to performance issues. Always use high-quality fuel and oil to keep the turbo running at peak efficiency.

5. When to Seek Professional Help

While some signs of turbo failure can be subtle, others can be more severe, and waiting too long to address the issue can lead to more serious repairs. If you're experiencing any of the symptoms mentioned above or have concerns about your truck’s performance, it's best to have Deer Park Diesel specialists inspect your vehicle.

Our trained technicians can diagnose whether your turbocharger is the problem and recommend the best course of action. Replacing or repairing a turbocharger isn’t a simple job that can be easily done at home, so seeking expert help is required for long-term engine health.

Address turbocharger issues early to keep your truck running efficiently.

Deer Park Diesel offers specialized turbocharger repairs and maintenance. Give us a call now to ensure your truck stays on the road!