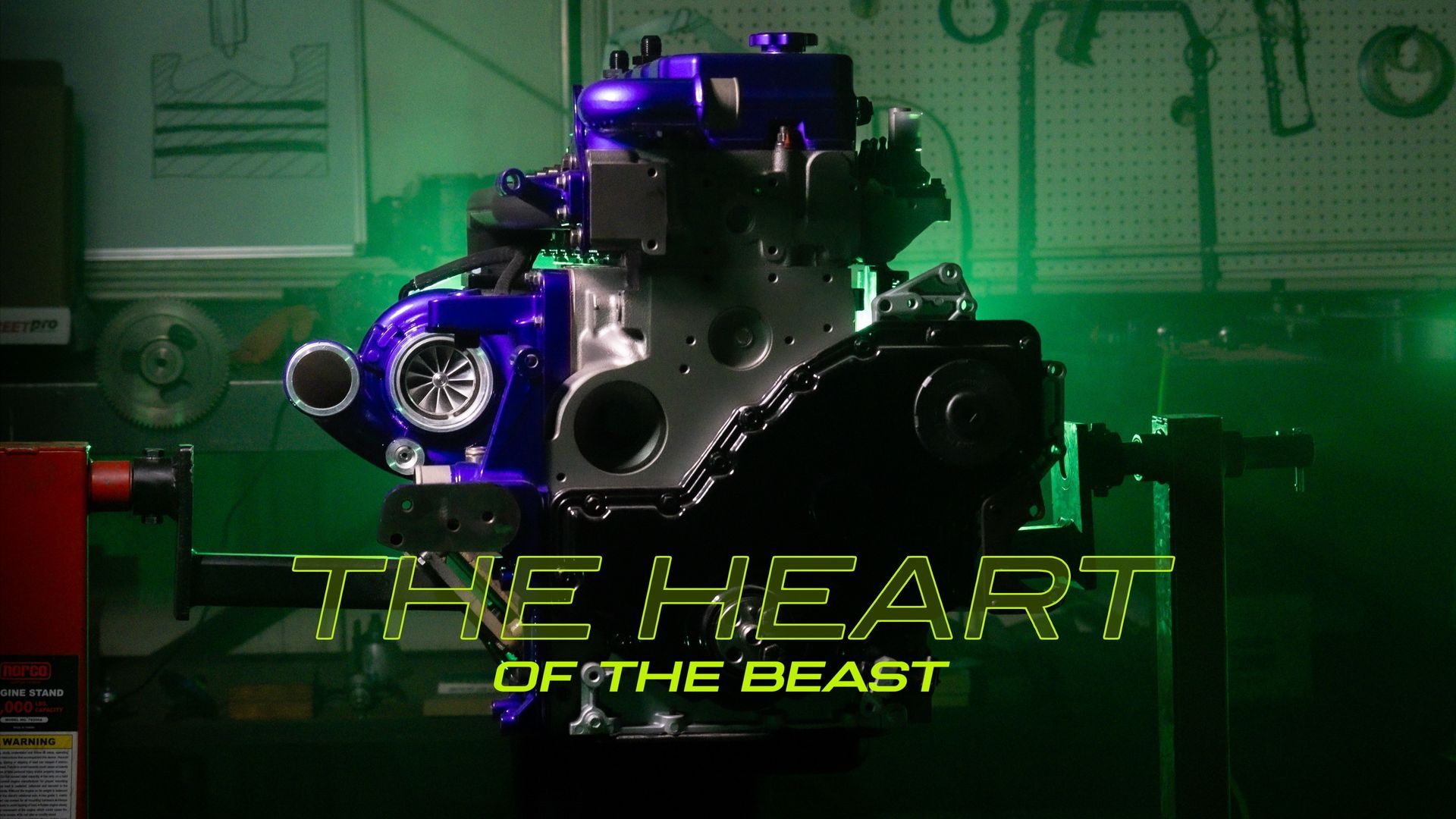

The Duramax 6.6L diesel engine has built a strong reputation among truck owners for its power, towing ability, and lifespan. Known for handling demanding work and long highway hauls, this engine is often the preferred choice for drivers who depend on their trucks for both work and recreation. However, when considering the long-term reliability of the Duramax, it’s essential to look beyond marketing claims and focus on real-world performance, common issues, and proper maintenance practices.

A Solid Track Record Over Multiple Generations

Since its introduction in 2001, the Duramax 6.6L has evolved through several generations, each improving on performance, emissions compliance, and fuel efficiency. Whether you’re driving an early LB7 or a modern L5P, the basic design of the engine has remained consistent in delivering strong torque and horsepower. Many Duramax owners report reaching 300,000 miles or more with proper care, and some well-maintained engines have crossed the half-million-mile mark.

Routine Maintenance Is the Key to Longevity

Even the most dependable engine needs regular maintenance to stay reliable over the long haul. Oil and filter changes should be performed on schedule, using the manufacturer’s recommended oil type and quality filters. The Duramax also benefits from routine fuel filter replacements, as clean fuel is essential for diesel performance. Skipping or delaying maintenance can shorten the lifespan of the fuel injectors, turbocharger, and other major components.

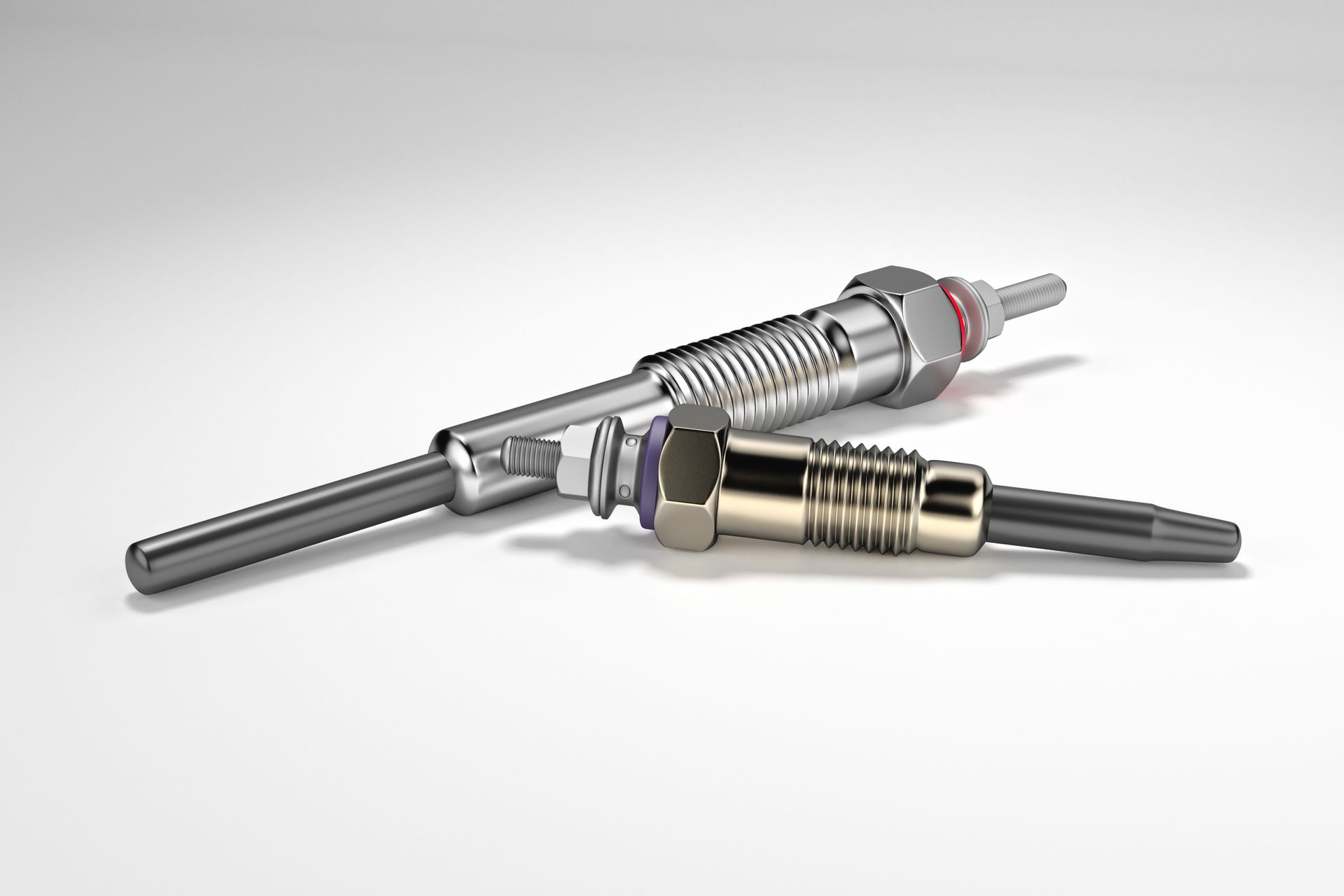

Known Issues to Watch Out For

No engine is perfect, and the Duramax 6.6L has a few issues that owners should monitor. Early LB7 models were known for injector failures, which could be costly to repair. Later models improved injector design, but fuel system components can still be vulnerable if maintenance is neglected. Some versions have also experienced head gasket failures, particularly in trucks used for heavy towing without proper cooling system upkeep. Being aware of these potential problems and addressing them early can prevent breakdowns and expensive repairs.

The Importance of Cooling System Care

A healthy cooling system is critical for diesel engines, especially when towing or working in hot conditions. Overheating can cause damage to head gaskets, pistons, and other critical parts. Regularly inspecting coolant levels, replacing coolant as recommended, and ensuring the radiator and intercooler are clean will help maintain optimal operating temperatures. Upgrading to heavy-duty cooling components can also extend engine life for drivers who push their trucks to the limit.

Fuel Quality and Additives

Diesel fuel quality plays a huge role in the longevity of your Duramax. Contaminated or low-quality fuel can lead to injector wear, poor combustion, and reduced efficiency. Many experienced owners use diesel fuel additives to enhance lubrication, prevent gelling in cold weather, and maintain the cleanliness of the fuel system. While not a substitute for maintenance, additives can help protect your investment and keep the engine running smoothly for years.

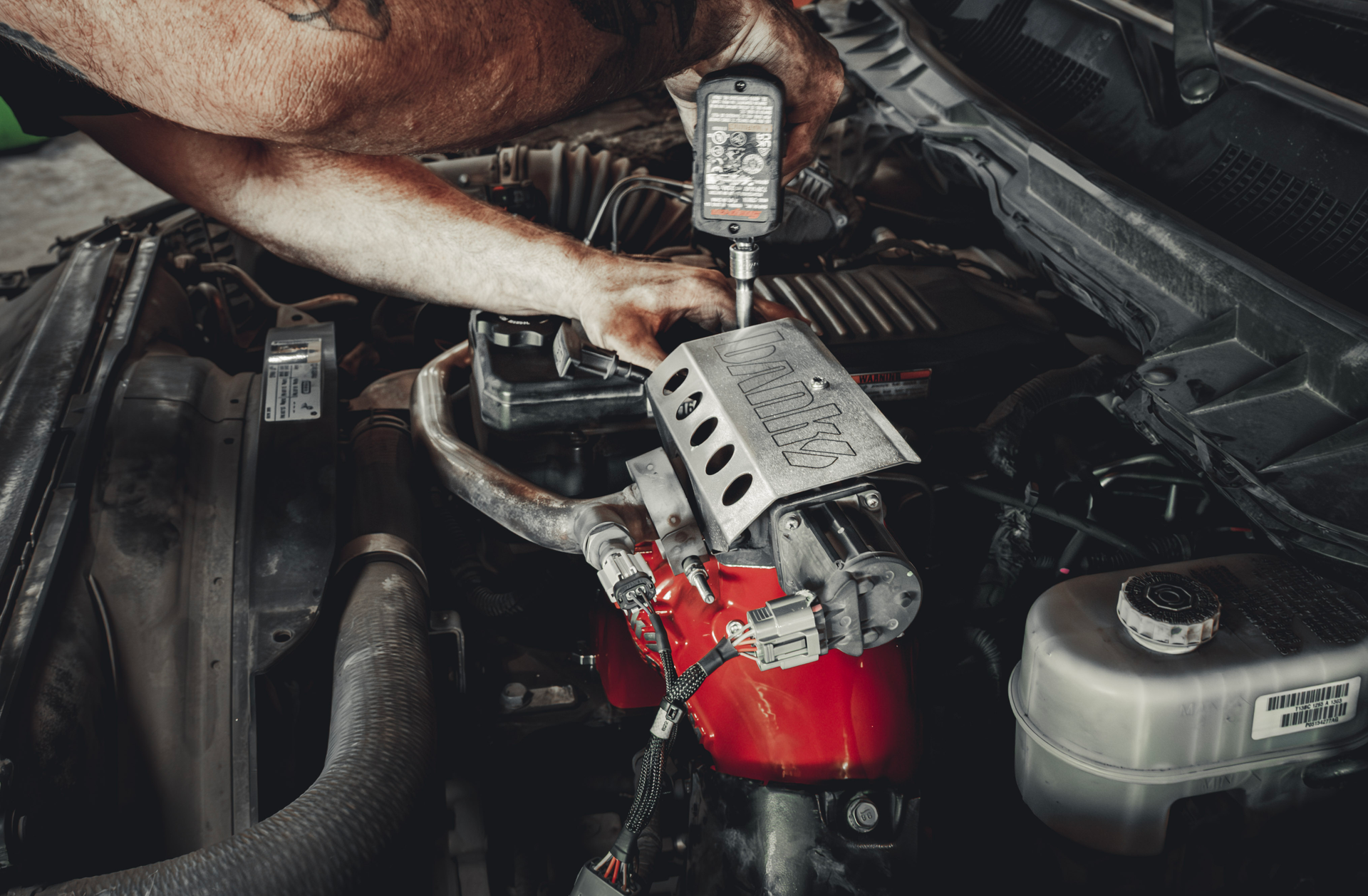

When Repairs Are Worth the Investment

Some owners hesitate to invest in repairs on an older diesel engine, but a well-maintained Duramax can justify the expense. Replacing injectors, turbos, or other key components may be costly, but when compared to the price of a new truck, extending the life of a dependable engine can be the more economical choice. Many truck enthusiasts choose to rebuild or upgrade their Duramax rather than start over with a newer model.

Keep Your Duramax Running Strong With Deer Park Diesel in Clayton, WA

If you own a Duramax 6.6L and want it to last for the long haul, consistent maintenance and early attention to problems are your best tools. At Deer Park Diesel in Clayton, WA, we specialize in Duramax service, repairs, and performance upgrades.

Whether you’re chasing 300,000 miles or aiming for even more, our team can help keep your truck reliable, powerful, and ready for whatever work or adventure you have planned.

6.6L Duramax Reliability Guide: LB7–L5P Problems, Fixes & What Spokane Area Truck Owners Should Know