"...call, email, or stop by Deer Park Diesel and we’ll help you pick the right solution before that little nut becomes a big problem."

Grid heater nut failure on a 6.7L Cummins is one of those "ounce of prevention beats a pound of cure" problems we see way too often at Deer Park Diesel.

If that tiny nut backs off and falls into the intake, it can get sucked into cylinder #6 and destroy the piston, head, and valves. Repair bills can easily climb into five figures.

The good news: there are several solid ways to fix the weak link before it fixes your engine. In this post we’ll walk through:

- What the grid heater nut problem actually is

- Three popular upgrade paths:

- Banks Monster Ram Intake & grid heater upgrade

- BD Diesel Killer Grid Heater Upgrade Kit

- S&B Intake Horn & grid heater delete plate

- Which option might be best for your truck and how we’d approach it in our shop

What’s actually failing?

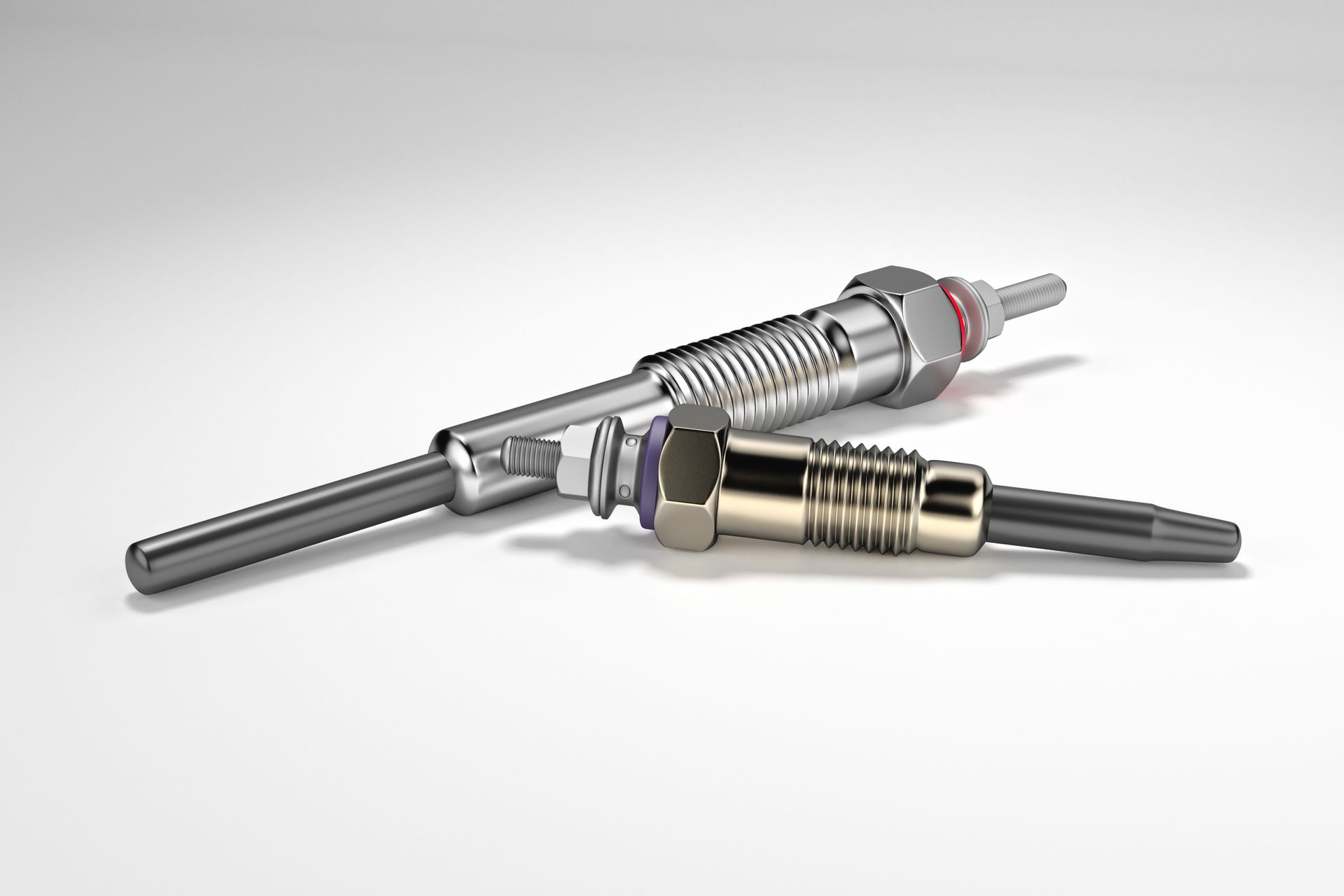

From the factory, your 6.7L Cummins uses a grid heater plate sandwiched between the intake horn and the head. It helps warm incoming air for cold starts.

The problem is the electrical connection design:

- ~200 amps are routed through a small stud and nut located inside the intake manifold.

- Over time, heat and vibration can cause that connection to deteriorate, arc, and loosen.

- When it finally lets go, the nut can drop into the intake runner for cylinder #6.

- Result: damaged piston, bent valves, cracked head – sometimes a full engine replacement.

So the goal of all these upgrades is the same:

Get that failure-prone nut and stud out of the airflow path, without ruining cold-start performance or emissions compliance.

OPTION 1: Banks Monster Ram Intake & Grid Heater Upgrade

Best for: Owners who want insurance and a performance bump, while staying emissions compliant.

The Banks Monster Ram is more than just a prettier intake elbow. It’s a complete re-think of the grid heater system:

- Replaces the factory grid heater plate with a high-flow billet intake plate, removing the internal nut and bolt entirely.

- Uses a vertical coil-style heater inside the Monster Ram elbow itself, so you still have intake air preheat without choking airflow.

- Outflows stock by over 88% on certain applications, improving throttle response and giving more headroom for tuning and future mods.

- Designed to be 50-state emissions compliant, retaining factory emissions equipment where required.

Pros

- Eliminates the killer grid heater nut entirely – the failure point is gone, not just re-engineered.

- Maintains or improves cold-start performance thanks to the coil heater.

- Noticeable airflow and response improvement; a good foundation for tuning, bigger turbo, etc.

- Clean, OE+ look under the hood.

Cons

- Highest up-front cost of the three options.

- Install is more involved than a simple plate swap (though it’s still a straightforward job in a well-equipped shop).

Who it fits best

- Trucks that tow heavy, have or will have performance mods, or see extreme temps but need to stay street-legal.

- Owners who want to “do it once, do it right” and are okay investing more up front to avoid a $15–20k engine later.

OPTION 2: BD Diesel Killer Grid Heater Upgrade Kit

Best for: Owners who want to keep a factory-style intake but fix the weak link.

The BD Diesel Killer Grid Heater Upgrade Kit focuses on the heart of the problem – that overloaded internal stud/nut connection.

From BD’s own description, the kit is “purpose-built to address a major flaw” where 200 amps are routed through that small nut and bolt in the intake. Over time, the connection deteriorates, arcs, and the nut can break off into the engine.

BD’s fix relocates the high-current connection outside the intake manifold, so there’s no loose hardware sitting above cylinder #6.

Pros

- Addresses the root electrical flaw without requiring an aftermarket intake elbow.

- Keeps an OE-style look under the hood.

- More budget-friendly than a full intake system.

- Good option if you’re otherwise stock and want protection without going “all in” on airflow mods.

Cons

- You still have a grid heater assembly in the intake path, so airflow isn’t as improved as a full Monster Ram or performance intake horn.

- Does not add the same performance bump as the Banks or S&B options.

Who it fits best

- Daily drivers or work trucks that are mostly stock.

- Owners primarily concerned with preventing an engine failure and less worried about maximum airflow.

OPTION 3: S&B Intake Horn & Grid Heater Delete Plate

Best for: Owners chasing max airflow and protection, who are comfortable with a grid-heater delete style solution where legal.

S&B offers an intake elbow (horn) and grid heater delete plate kit for the 6.7L Cummins. The idea is straightforward:

- Replace the restrictive factory elbow and grid heater plate with:

- A high-flow intake horn, and

- A grid heater delete plate that removes the failure-prone heater hardware from the intake stream.

S&B advertises this as a way to “avoid catastrophe” by eliminating the factory grid heater and increasing airflow at the same time.

Pros

- Removes the risk of the factory grid heater nut dropping into the engine.

- Excellent airflow – S&B markets this as one of the best-flowing elbows on the market.

- Typically more cost-effective than a high-end full system like Banks, depending on configuration.

- Clean install and a noticeable performance and drivability improvement when paired with other mods.

Cons

- In some configurations it’s essentially a grid heater delete, which can:

- Impact cold-start performance in harsh winter climates if no alternate pre-heat is used.

- Have emissions implications, depending on your local regulations and how the truck is set up.

- Not designed with the same coil-heater solution that Banks uses; if you need serious cold-weather preheat away from a block heater, that’s worth thinking about.

Who it fits best

- Warmer-climate trucks or rigs that are plugged in overnight when it’s really cold.

- Performance-focused owners who want maximum flow and are comfortable with a more aggressive approach to the grid heater issue, where legal.

So which option is right for your 6.7L Cummins?

Here’s how we’d break it down at Deer Park Diesel:

“I tow, I work this truck, and I need it to start in Eastern Washington winters.”

- Top pick: Banks Monster Ram intake with grid heater upgrade.

- You get reliability, cold-weather performance, and better airflow, all while staying emissions friendly.

“I’m mostly stock and just want to make sure that nut never grenades my engine.”

- Top pick: BD Diesel Killer Grid Heater Upgrade Kit.

- Fixes the critical failure point and keeps the rest of the intake system stock-looking and simple.

“I’m building a performance truck and want max flow with the risk gone.”

- Top pick: S&B intake horn and delete plate, possibly paired with tuning and other airflow mods.

- Just be realistic about your climate, cold starts, and local emissions rules.

How we handle grid heater prevention at Deer Park Diesel

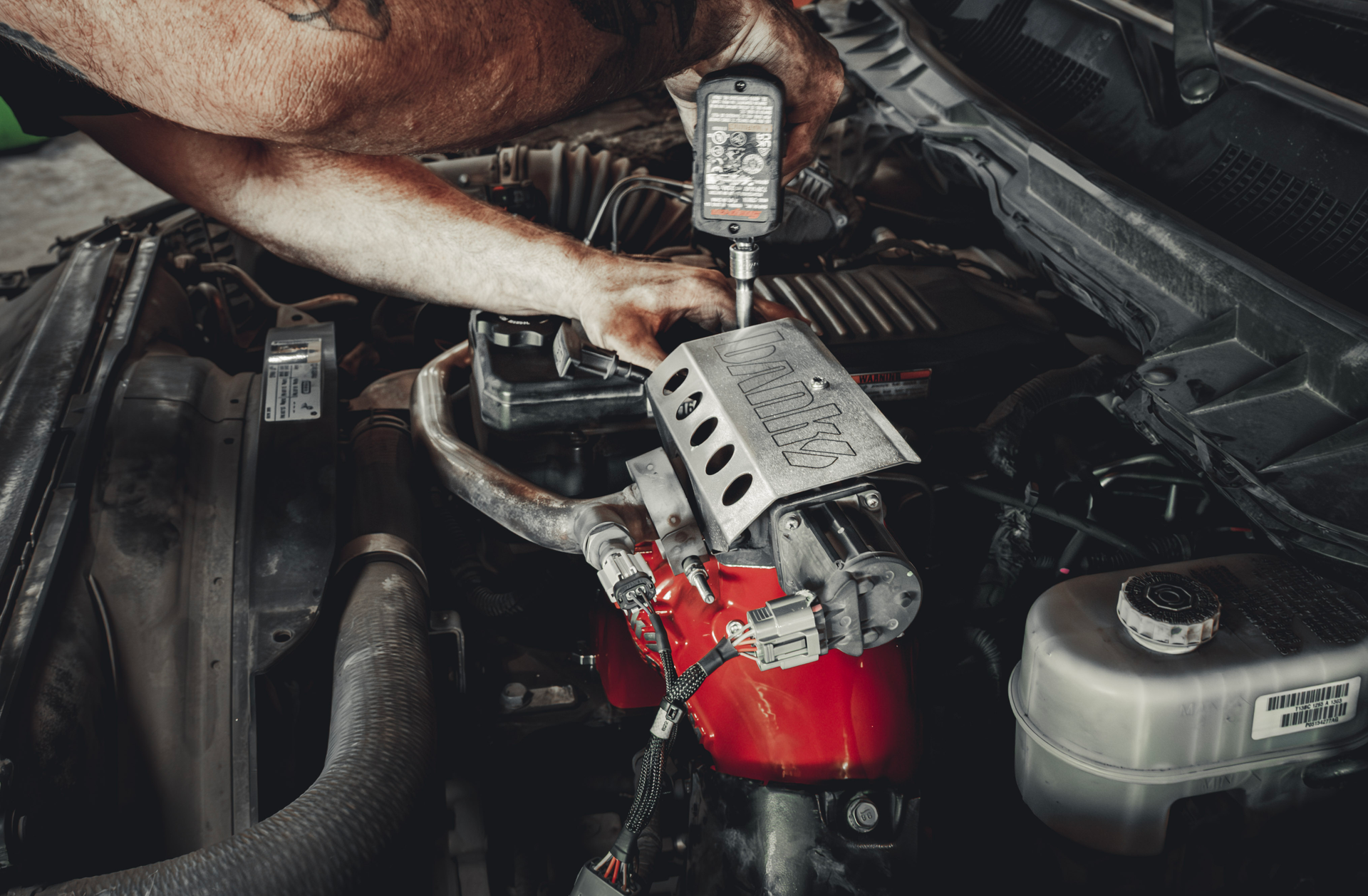

When a 6.7L Cummins rolls into our shop here in Deer Park, we typically:

- Inspect the existing grid heater hardware

- Check for signs of arcing or heat damage at the connector.

- Look for soot and buildup in the intake that may be hurting airflow anyway.

- Discuss how you use the truck

- Heavy towing vs light duty

- Winter starting needs (block heater access, parking situation)

- Future plans: tuning, turbo, injectors, etc.

- Recommend the right path for your use case

- Banks Monster Ram for a “forever fix” that also boosts performance.

- BD kit for a cost-effective reliability upgrade on a mostly stock truck.

- S&B horn and delete plate for the airflow-focused builds where it makes sense.

- Do a clean, documented install

- Torque specs followed, wiring secured, no “mystery splices.”

- We can pair the work with an intake cleaning, EGR service, or other preventative maintenance while we’re in there.

Ready to protect your 6.7?

If you’re driving a 6.7L Cummins and haven’t addressed the grid heater nut yet, you’re rolling the dice on an engine that should otherwise run you several hundred thousand miles.

We’re happy to:

- Go over Banks vs BD vs S&B in the context of your truck and budget

- Put together a quote that includes parts, install, and any additional recommended maintenance

- Schedule the work so your truck is down as little as possible

You can call, email, or stop by Deer Park Diesel and we’ll help you pick the right solution before that little nut becomes a big problem.

6.6L Duramax Reliability Guide: LB7–L5P Problems, Fixes & What Spokane Area Truck Owners Should Know