a comprehensive guide to the fundamental strengths, weaknesses, and common repairs on Duramax engines

If you own a Chevy or GMC HD truck in the Spokane / Deer Park area, there’s a good chance it has a 6.6L Duramax under the hood. It’s one of the most popular diesel engines we see at Deer Park Diesel, and a question we hear all the time is:

“Are 6.6L Duramax engines actually reliable?”

Overall, yes—the 6.6L Duramax is a solid platform. But each generation (LB7, LLY, LBZ, LMM, LML, L5P) has its own strengths, weak points, and “gotchas” you’ll want to understand before you buy or repair one.

This guide is written from the perspective of a family-owned diesel shop in Deer Park, WA, serving Spokane, North Spokane, Deer Park, Chattaroy, Clayton, and the surrounding area. Our goal is to help you make smart decisions about your truck.

Common Problems for ALL generations:

- No fuel lift pump. Injection pump creates it’s own vacuum, pulling fuel from the tank. The flexible sections in the fuel lines often collapse over time, creating restriction. This results in low fuel rail pressure. The L5P is the only exception to this, as it was *finally* designed with a factory lift pump.

- THE FIX: Install an aftermarket fuel lift pump system with additional filtration, like the Airdog 5G.

- Steering/suspension components wear out over time, especially true in leveled/lifted trucks with larger tires. The stock components (idler/pitman arm, tie rods, ball joints) don’t hold up, and become sloppy creating soft steering and wandering at highway speeds.

- THE FIX: Install upgraded, heavier duty steering components like the Ultimate Front End kit from Kryptonite.

- While the engines and transmissions are very stout on most iterations, it is possible to create enough horsepower through simple modifications (tuning, injectors, turbo) to easily overcome their limits, resulting in broken crankshafts and premature transmission failure.

- THE FIX: Know the risk! Don’t run big injectors, turbo, and a hot tune on a stock bottom end, unless you’re willing to pay the price.

- For all DPF equipped models, aftertreatment systems are going to be problematic. The diagnostic and repair procedures can be unpredictable and time consuming, creating potentially expensive repair bills.

- THE FIX: Not much you can do here, except do your best to minimize idle time and stay current on maintenance.

Below, we break down each specific generation in more detail.

LB7 Duramax (2001–2004): Simple & Strong, But Injectors Are the Big Story

The OG 6.6L Duramax found in 2500HD and 3500 trucks starting in 2001.

Highlights:

- No DPF, no DEF

- Uses a CP3 injection pump

- Good fuel economy and solid bottom end

Common problems:

- Injectors: The big one. LB7 injectors are known to fail—cracking, leaking, or having balance issues. Many trucks have already had injectors replaced once or even twice.

- Fuel in the oil, misfires, hard starts, and excessive smoke can all point to injector problems.

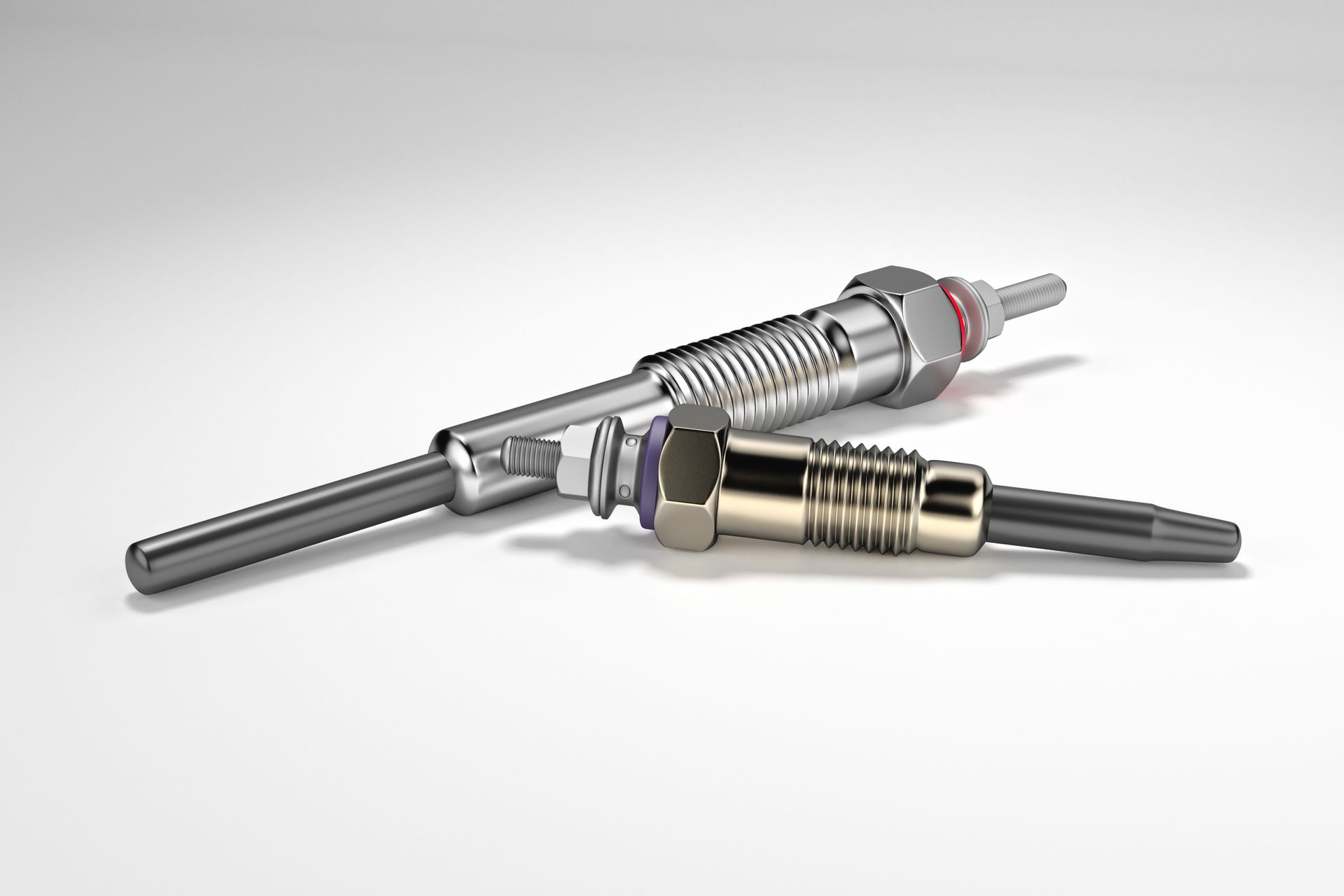

- With the age of these trucks, you’ll also see the usual: oil leaks, worn front ends, tired glow plugs, etc.

- No fuel lift pump (CP3 runs on vacuum), creating fuel supply issues over time

Pros:

- Simple emissions system

- Good power for the era

- When the fuel system is healthy, they can run a long time

Cons:

- Injector replacement is expensive and labor-intensive

- Every LB7 is now 20+ years old, so age is a factor on everything

Reliability verdict:

When injectors are addressed properly and the truck is maintained, LB7s can be very reliable. But

injectors are a non-negotiable expense on this platform.

At Deer Park Diesel:

We routinely perform

LB7 injector diagnostics and replacement, fuel system inspections, and general reliability checks. If you’re looking at buying an older Duramax around Spokane, an LB7 absolutely needs an injector history review and a proper inspection.

LLY Duramax (2004.5–2005): More Power, Watch the Temps

What changed:

- Variable geometry turbo (VGT)

- EGR added

- Slight bump in power and torque over the LB7

Common problems:

- Overheating under load: Especially when towing or climbing grades (hello, North Idaho hills). A marginal cooling system and restrictive airflow can cause high temps.

- Head gaskets: Long-term overheating or aggressive tuning can contribute to head gasket failure.

- EGR-related carbon buildup and sticking issues.

Pros:

- Better drivability with the VGT turbo

- Fewer injector issues than the LB7

- Good towing performance

Cons:

- Cooling system is the weak link

- Potential for expensive head gasket jobs

- More emissions pieces than the LB7

- Potential wiring issues on this platform, specifically injector connectors and FICM

- Still no lift pump

Reliability verdict:

A well-maintained LLY with a clean cooling stack, good thermostats, and responsible tuning can be reliable. But

overheating and head gaskets are the big concerns to investigate.

At Deer Park Diesel:

For LLY trucks, we focus on

cooling system health, head gasket diagnostics, and EGR system service. If your LLY runs hot towing into Spokane or up to Priest Lake, that’s not something to ignore.

LBZ Duramax (2006–2007 Classic): The “Gold Standard” for Many Owners

Ask a lot of Duramax owners which engine they’d pick, and LBZ is usually the top of the list.

What makes LBZ special:

- More power and torque than LLY

- Still no DPF, DEF, or complex aftertreatment systems—only a catalytic converter and EGR from the factory

- Strong internals and the proven CP3 injection pump

Common problems:

- Normal high-mileage diesel issues: injectors eventually wear out, water pump leaks, glow plug failures, oil leaks

- No single “Achilles heel” like LB7 injectors or LML CP4 pumps

- Rust and chassis wear often become bigger concerns than the engine itself

Pros:

- Widely regarded as one of the most reliable Duramax platforms

- Great towing manners paired with the Allison transmission

- Strong aftermarket support

Cons:

- They’re in high demand and often priced accordingly

- Clean, unmolested LBZ trucks can be hard to find

Reliability verdict:

If you find a clean, well-maintained LBZ, it’s one of the safest bets in the Duramax world. For many owners, this is the “sweet spot” between power, simplicity, and longevity.

At Deer Park Diesel:

We see a lot of

LBZ trucks used for hauling, RVs, and work around Spokane and Deer Park. Our typical work includes

preventive maintenance, injector testing, water pump replacement, and performance-minded but safe upgrades.

LMM Duramax (2007.5–2010): Strong Engine, More Emissions

With the LMM, emissions rules tightened and DPF systems came in.

Key changes:

- Diesel particulate filter (DPF)

- More sophisticated EGR system

- Still runs the CP3 pump

Common problems:

- DPF issues: Frequent regens, clogged filters, and sensors causing codes and derates, especially on trucks that do lots of short trips or idling.

- EGR valve and cooler problems due to carbon buildup.

- Transmission cooler line leaks are also common on these years.

- Glow plug and sensor faults with age.

Pros:

- Strong base engine and bottom end

- Good towing and power

- CP3 pump is generally reliable

Cons:

- Emissions components can be expensive to diagnose and repair

- Trucks used for stop-and-go or short commutes around Spokane can have more DPF-related headaches

Reliability verdict:

Mechanically, the LMM is solid.

Most “problems” are emissions-related, not bottom-end failures. Good maintenance and driving patterns (getting the truck properly up to temp and allowing full regens) go a long way.

Note: From a legal and environmental standpoint, emissions components must remain in place and functional. We do not recommend or perform illegal DPF/EGR delete work.

At Deer Park Diesel:

For LMM owners, we offer

DPF/EGR diagnostics, regen troubleshooting, fuel system testing, and maintenance plans tailored to how you actually drive (work truck, tow rig, or mixed use). We do all of this

while keeping emissions components legal and functional.

LML Duramax (2011–2016): Strong Performer with a CP4 Warning

The LML steps power up again, adds DEF, and changes the fuel system.

Key changes:

- Higher horsepower and torque

- DEF/SCR system added alongside the DPF

- Switched to the Bosch CP4.2 high-pressure fuel pump

Common problems:

- CP4.2 pump failure: This is the big known risk. When a CP4 fails, it can send metal through the entire fuel system—contaminating injectors, rails, lines, and the tank. Repair can be very costly.

- DEF system and NOx sensor issues

- DPF and EGR problems similar to LMM but with updated hardware

Pros:

- Excellent power and drivability

- Good fuel economy when everything is working

- When the fuel system is healthy, these trucks can be long-lived

Cons:

- CP4 failure risk can turn into a major repair bill

- Emissions system adds more components that need to be kept in good shape

At Deer Park Diesel:

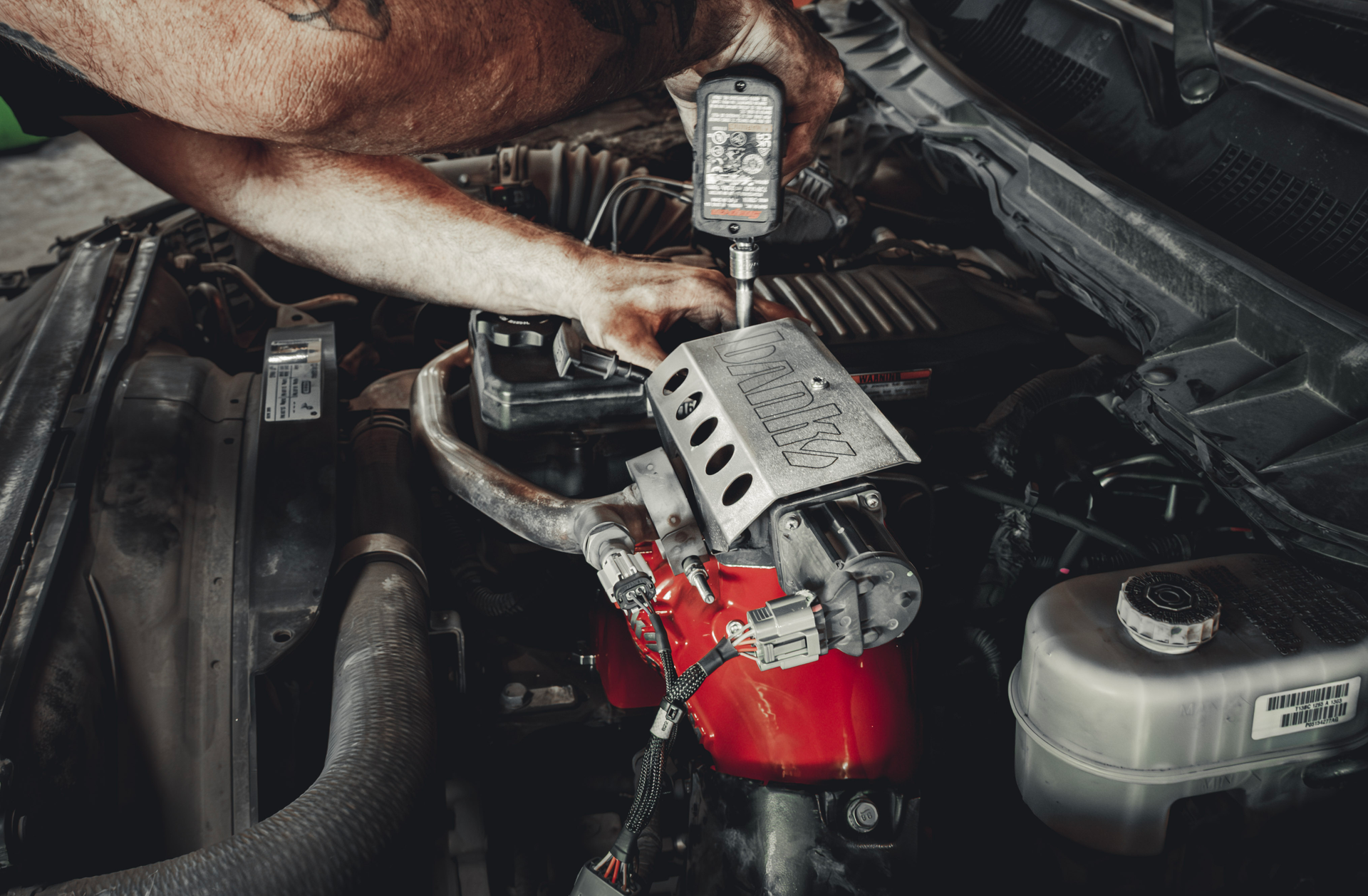

With LML trucks, we pay close attention to

fuel system health, using proper diagnostics to catch problems early. We can:

- Diagnose low rail pressure and hard-start issues

- Inspect for early signs of pump or injector trouble

- Help you build a maintenance plan that protects your investment

We’re happy to talk through your options if you’re worried about CP4-related problems or considering upgrades.

L5P Duramax (2017–Present): Newer, Strong, and Electronics-Heavy

The L5P is a major redesign and currently powers late-model GM HD trucks all over the Spokane area.

Key changes:

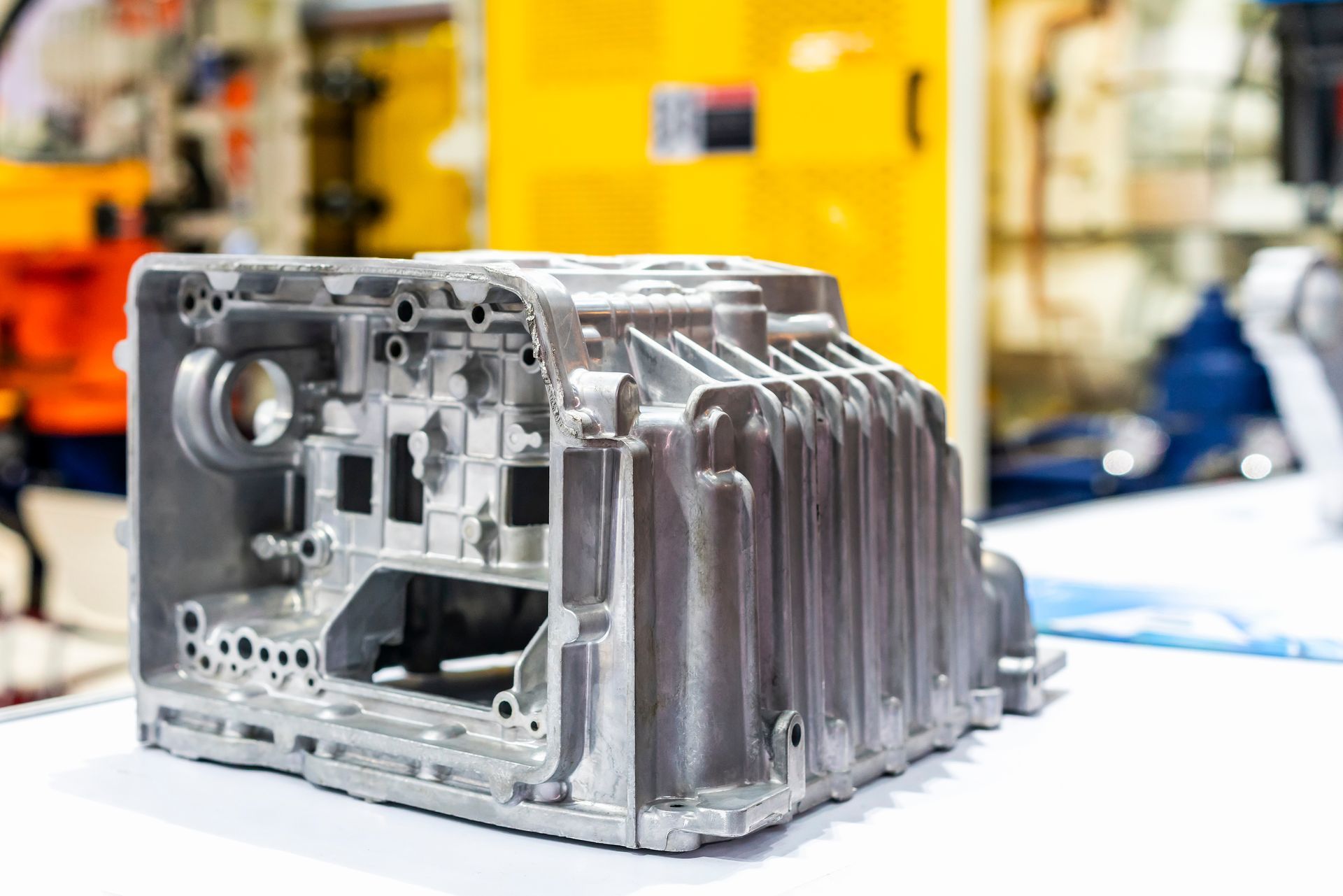

- Stronger block, heads, and rotating assembly

- Completely redesigned fuel system (no CP4 pump)

- Much higher factory power and torque

- Updated emissions and electronic controls

Common problems reported so far:

- Sensor and electrical issues (MAP/EGT/NOx sensors, etc.)

- Occasional water pump or cooling system complaints

- Normal wear items as mileage climbs

Pros:

- Very strong stock power and towing capability

- Robust engine design

- Better fuel system design than the previous CP4 era

Cons:

- More electronics and modules; diagnostics can be more involved

- Newer trucks mean higher parts and labor costs in general

Reliability verdict:

So far, the L5P is proving to be a very solid engine

with far fewer horror stories than the CP4-equipped LML. Most issues we see relate more to sensors, tuning choices, and maintenance than any fundamental design flaw.

At Deer Park Diesel:

We provide

factory-style diagnostics, maintenance, and repair for L5P trucks, from work fleets to RV tow rigs. That includes

emissions diagnostics, sensor replacement, routine services, and reliability inspections before big trips.

What Actually Determines Duramax Reliability?

Regardless of the badge on the fender, three things matter most:

1. Maintenance

- Regular oil and filter changes with correct fluids

- Fuel filter changes on schedule (critical on any common-rail diesel)

- Coolant service and cooling system inspections

- Keeping the cooling stack clean (big deal for trucks that tow in hot weather or dusty conditions)

2. How the Truck Is Used

- Heavy towing with aggressive or poorly written tuning can shorten engine and transmission life.

- Lots of short trips around Spokane, Deer Park, or town driving are harder on DPF/DEF/EGR systems.

- Long periods of idling also create issues for emissions systems.

3. Quality of Previous Repairs & Modifications

- Cheap parts, “farm fixes,” and hacked wiring will always cause reliability problems.

- Poorly executed engine, fuel system, or transmission work will come back to haunt you.

- Random deletes or backyard tuning can create more problems than they solve—and can make future diagnostics a nightmare.

How Deer Park Diesel Can Help Duramax Owners

If you own (or are looking to buy) a 6.6L Duramax in the Spokane / Deer Park area, here’s how we can help you get the most out of it:

Duramax Pre-Purchase & Reliability Inspections

- Full scan for active, stored, and pending codes

- Fuel system testing and injector balance rate review

- Cooling system and head gasket checks

- Emissions system health check (DPF/DEF/EGR)

- Underbody, front end, and chassis inspection

Common Duramax Repairs & Services We Handle

- LB7–L5P diagnostics and repair

- Injector testing and replacement

- Head gasket and cooling system repairs

- Fuel system cleaning, testing, and component replacement

- DPF/DEF/EGR diagnostics and repairs (where applicable)

- Regular maintenance tailored to heavy towing, work use, or mixed driving

Thinking About a Duramax, or Already Own One?

If you’re in Spokane, Deer Park, or the surrounding areas and you:

- Want a pre-purchase inspection on a used Duramax

- Need help tracking down a hard-start, smoke, or lack-of-power issue

- Are concerned about injectors, CP4 failures, or head gaskets

Deer Park Diesel can walk you through your options and give you a clear picture of what your truck needs.

Ready to protect your 6.6L Duramax?

Get in touch with Deer Park Diesel in Deer Park, WA to schedule a diagnostic or inspection, and keep your truck earning its keep for the long haul.