Turbochargers are one of the most powerful upgrades to modern diesel trucks, especially on engines like the 6.7L Cummins and the 6.7L Powerstroke. These systems provide the torque and towing power that diesel owners depend on. But when they fail, it can lead to expensive repairs and frustrating downtime. The good news is that most turbo failures don’t happen overnight.

There are patterns and causes behind them, and with the right maintenance and driving habits, many of those issues can be avoided.

Why the 6.7L Turbo Works So Hard

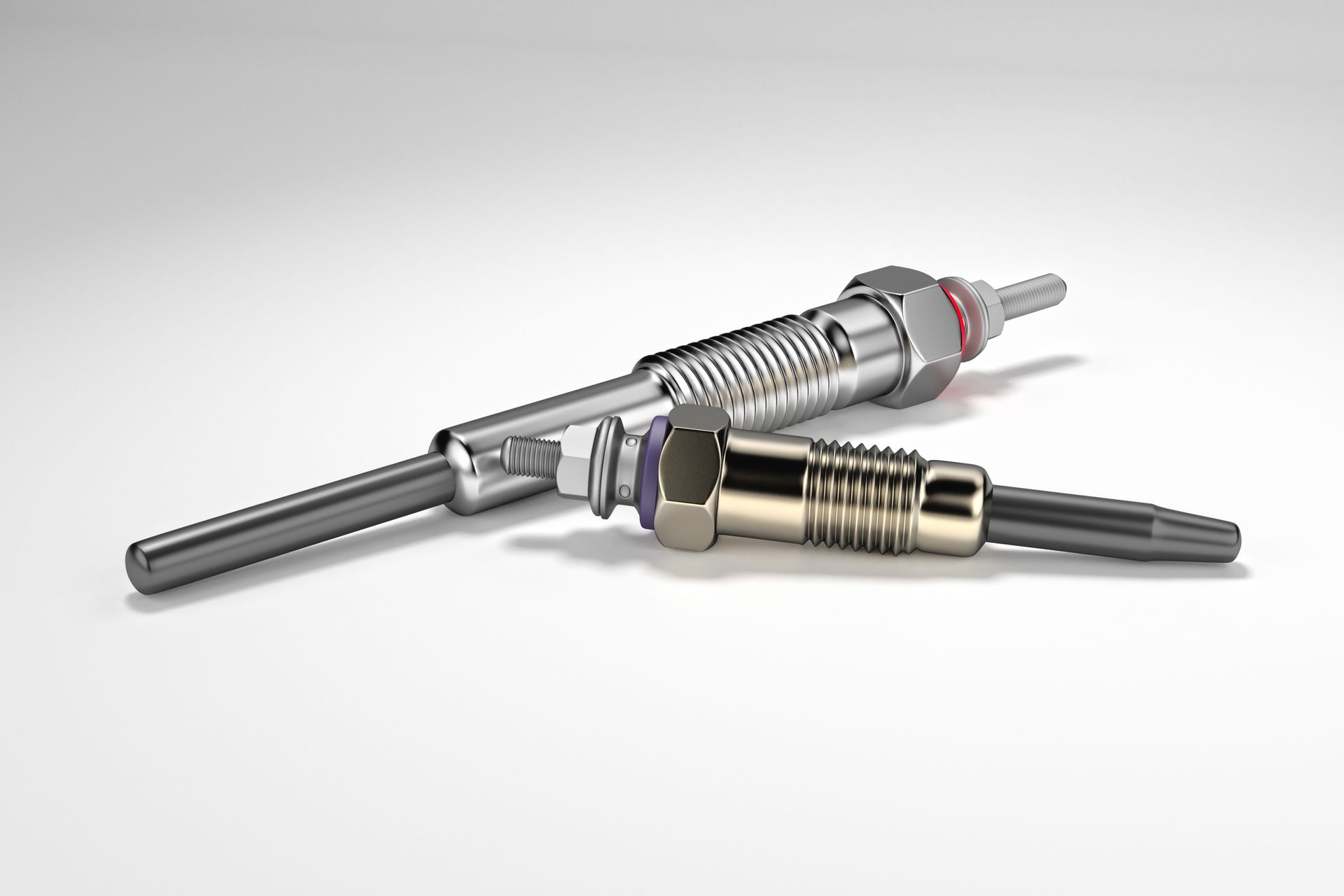

Both the Cummins and Powerstroke 6.7L engines use variable geometry turbochargers (VGTs), which adjust to driving conditions for better performance and efficiency. These turbos spool quickly at low RPMs and adjust for high boost when towing or accelerating. Because they’re always adapting and constantly exposed to high exhaust temperatures, they work harder than fixed-geometry turbos.

That makes regular maintenance and clean driving habits even more important.

Signs a Turbo May Be Headed for Trouble

Turbo problems don’t always start with a dramatic failure. Early symptoms often include slow acceleration, black smoke from the exhaust, or a whistling sound that wasn’t there before. You might notice a check engine light or poor fuel economy. If the turbo vanes are sticking, you could feel hesitation or surging.

These symptoms often show up long before the turbo actually fails completely, which means there’s usually time to prevent a major repair if you act early.

What Causes Turbo Failure on the 6.7L Cummins and Powerstroke

One of the most common issues is carbon buildup inside the turbo housing, especially on the VGT mechanism. Over time, soot and debris from the exhaust coat the moving parts, making them sluggish or stuck. Oil contamination is another big cause. Since the turbo relies on a thin film of oil to keep the shaft spinning freely, any lack of lubrication or dirty oil can quickly cause wear on the bearings.

Aggressive driving on a cold engine, or shutting the truck off immediately after towing, can also reduce the turbo’s lifespan by limiting oil flow when it’s needed most.

How Does Oil Maintenance Make a Big Difference

Both 6.7L engines need clean, high-quality oil to keep the turbo healthy. The turbo spins at speeds over 100,000 RPM and relies on oil to stay cool and lubricated. Delaying oil changes or using the wrong oil grade increases the risk of sludge or varnish forming inside the feed lines. If oil doesn’t reach the bearings fast enough, even briefly, heat and friction can damage the shaft.

Sticking to factory oil change intervals and using the manufacturer-recommended oil type is one of the easiest ways to protect your turbo.

Driving Habits That Extend Turbo Life

Letting the engine idle for a minute after a hard tow or highway run gives the turbo a chance to cool down while still getting full oil circulation. This helps prevent coking, where oil burns onto the hot shaft and creates a carbon crust. Avoid flooring it on a cold engine, especially in freezing weather, since the oil hasn’t fully circulated and the turbo is still dry. Try to drive gently for the first few minutes and give the turbo time to spool down before shutting the engine off.

These small habits can make a huge difference in turbo longevity.

Should You Clean or Replace a Sticky VGT?

Some turbo issues on the 6.7L Powerstroke and Cummins can be resolved by cleaning the vanes or replacing the actuator, especially if caught early. In other cases, the buildup may be too severe, and replacement is the only real fix. Technicians can use scan tools to test turbo response and determine whether the VGT is sticking or responding normally.

If the turbo is making noise or if there’s shaft play, replacement is usually the safer option.

What the Technician Looks for During Turbo Inspection

A proper turbo inspection starts with a look at the shaft for movement or damage. Side-to-side or in-and-out play suggests worn bearings. The intake and exhaust sides are checked for oil leaks, cracks, or soot buildup. Actuators and sensors are tested to see if the VGT system is responding to commands. Boost pressure tests and data logging during a road test help confirm what’s going on.

We can catch turbo problems before they get worse if you bring the truck in when symptoms first appear.

Diesel Repair in Clayton for Cummins and Powerstroke Trucks

Whether you’re driving a Ram with the 6.7L Cummins or a Ford Super Duty with the 6.7L Powerstroke, keeping your turbo healthy means staying ahead of wear and buildup, if your truck feels underpowered, smokes under load, or has a weird whistle or flutter, it’s time for a professional to take a look.

Get Expert Turbo Service at Deer Park Diesel in Clayton, WA

At

Deer Park Diesel, we work on 6.7L Cummins and Powerstroke engines every day. If your turbo isn’t performing like it used to, we’ll inspect the system, clean what can be saved, and replace what can’t. Call today to schedule a diagnostic and keep your truck pulling strong.

6.6L Duramax Reliability Guide: LB7–L5P Problems, Fixes & What Spokane Area Truck Owners Should Know