Cold weather has a way of exposing weak spots in diesel trucks, and glow plugs are high on that list. When they are healthy, the engine fires up quickly, even on frosty mornings. When they are tired, you start to notice longer cranking, rough idle after start, and clouds of white smoke that were not there last winter.

Why Glow Plugs Matter For Cold-Weather Diesel Starts

Diesel engines rely on very high compression to ignite fuel, and cold metal is not friendly to that process. Glow plugs preheat the combustion chambers so the air and fuel reach ignition temperature quickly, instead of cranking forever while the engine tries to warm itself. On a warm day, you may get away with weak plugs, but in cold weather, they become the difference between a quick start and a dead truck.

Modern systems control glow plug timing and intensity electronically, so the engine computer expects a certain amount of help from them. When that help disappears, you are asking a cold diesel to light off without its normal assist, and that is when starting issues begin.

Early Warning Signs Your Glow Plugs Are Weak

Glow plugs usually fade over time instead of failing instantly. If you pay attention, your truck will give you some hints. Common early signs include:

- Longer crank times on cool mornings compared with last year

- Rough idle and shaking for the first few seconds after the engine finally starts

- A puff of white or gray smoke right after start ,that clears once the engine warms

You might also notice the glow plug or check engine light coming on and staying on after start. When our technicians hear “it still starts, but it takes longer than it used to when it is cold,” glow plugs and their control circuits are high on the list.

Cold-Weather Symptom Timeline: From Annoyance To No-Start

Most glow plug problems walk through a predictable timeline as the weather gets colder. At first, you just notice a little extra cranking and some rough running for a few seconds, but the truck still gets going. As temperatures drop further, the rough running lasts longer, the smoke increases, and you may need a second crank cycle to keep it running.

Once several plugs are completely dead, a true cold snap can turn those annoyances into a no-start. The starter might crank strongly, batteries are good, the fuel system is healthy, but the engine simply does not light without excessive cranking. That is usually when we see trucks towed in on the first really cold morning of the season.

Other Problems That Can Mimic Bad Glow Plugs

Glow plugs get blamed for a lot of cold-weather starting issues, but they are not always the only culprit. Weak batteries, corroded cable connections, and a tired starter can spin the engine too slowly, which makes cold starts hard even with good plugs. Air in the fuel system, gelled fuel, or low fuel pressure can cause long crank times and smoke that looks similar on the surface.

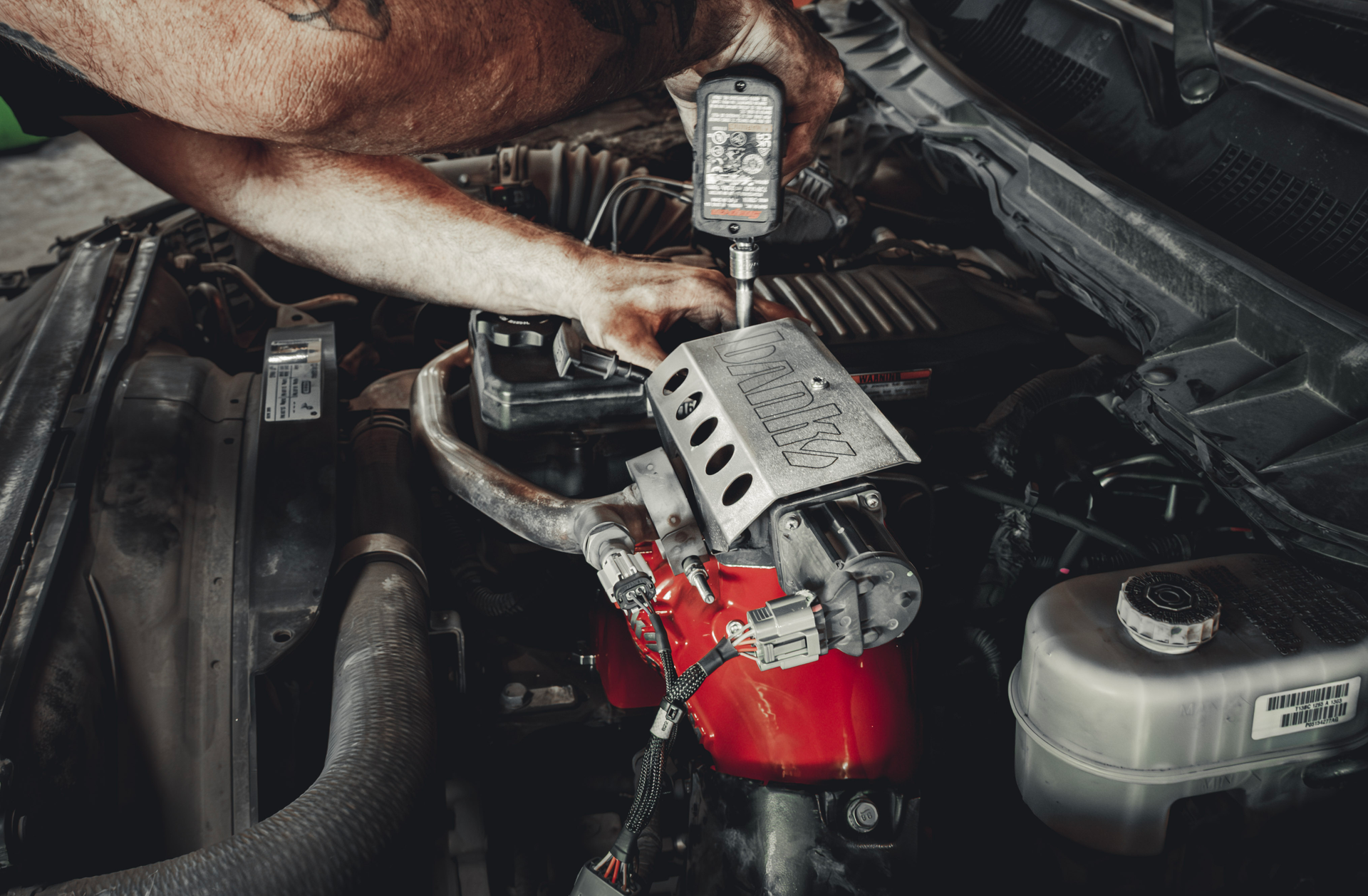

There are also control side issues, like failed glow plug modules, relays, or wiring faults, that keep good plugs from heating at all. That is why a proper diagnosis matters. In the shop, we test individual plugs, check control circuits, and measure battery performance instead of just throwing parts at the problem.

When It Is Time To Replace Glow Plugs

You do not have to wait until the truck refuses to start to plan glow plug replacement. If testing shows multiple plugs with high resistance or no activity, it makes sense to replace the full set rather than chasing them one by one as they fail. That is especially true on higher mileage engines that have seen several winters.

We also look at service history and how the truck is used. A work truck that lives outside and sees early morning cold starts all winter deserves a more proactive approach than a diesel that only sees occasional use. If you are already in the bay for battery and starting system checks, that is a good time to have the glow system evaluated so everything works together.

Owner Habits That Help Your Glow Plugs Last

You cannot change the weather, but a few habits reduce stress on the starting system. Keeping batteries in top shape and replacing them before they are completely exhausted helps the glow system and starter work correctly. Using the right grade of engine oil and appropriate winter fuel or additives makes cold cranking easier on everything.

It also helps to let the glow cycle complete before you crank. Turning the key straight to start without giving the system its preheat time makes life harder on both the engine and the plugs. If your indicator light behavior changes from what you are used to, that alone can be a useful clue that something in the system has shifted.

After-The-Fix Care For Reliable Winter Starts

Once weak glow plugs and related issues are corrected, you can get more out of the repair with a little ongoing attention. Listen to how the engine sounds on the first start of the day and note any changes as the season goes on. If cranking time starts creeping up again, having it checked early keeps you ahead of another no-start.

Pairing glow plug replacement with a starting and charging system check gives you a more complete picture of winter readiness. That way, you know plugs, batteries, and the starter are all ready for cold mornings, not just one piece of the puzzle.

Get Glow Plug Replacement in Clayton, WA with Deer Park Diesel

If your diesel truck has been cranking longer, stumbling on cold starts, or throwing glow plug warnings, this is the right time to address it before winter gets harsher. We can test your glow plugs, control module, and starting system, then replace worn parts so your truck lights off with confidence.

Schedule glow plug replacement in Clayton, WA with

Deer Park Diesel, and we will help keep your cold-weather starts reliable all season.

6.6L Duramax Reliability Guide: LB7–L5P Problems, Fixes & What Spokane Area Truck Owners Should Know