The 5.9L and 6.7L Cummins engines are both known for their durability and torque, but even these workhorse engines come with a set of common problems. Whether you’re running an older 5.9L Ram or a newer 6.7L model, knowing what to watch for can help you avoid downtime and extend the life of your diesel truck.

Let’s take a look at the most frequent issues with each engine and how they compare in reliability, complexity, and repair trends.

Common 5.9L Cummins Engine Problems

The 5.9L Cummins-powered Dodge Ram trucks from 1989 through 2007 are still widely respected for their simplicity and longevity. But over the years, several issues have become familiar territory for owners and diesel techs alike.

Gear Case Leaks & Dowel Pin Problems

One known issue is gear case oil leaks—often tied to the infamous “killer dowel pin.” If left unsecured, this steel pin can vibrate loose, fall into the timing gears, and destroy the engine. Most older 5.9s benefit from a timing cover reseal and a dowel pin tab to prevent serious damage.

Fuel System Failures

The 5.9 saw two major fuel systems over its life. The 1998.5–2002 models use a VP44 pump, which is prone to failure—especially if the lift pump isn't doing its job. From 2003–2007, the engine switched to a common-rail system with more reliable CP3 pumps, but high-pressure fuel injectors can fail over time, causing rough idling, fuel dilution, or even piston damage if left unchecked.

Cylinder Head Gasket Leaks

While the 5.9 has a strong cast-iron head, high-performance tuning or overheating can cause the head gasket to fail. A leaking gasket may cause coolant loss, overheating, or white smoke from the exhaust—common signs that the head needs to come off.

Water Pump Failure

The water pump is a frequent wear item across all 5.9s throughout the years. Failure typically shows up as a coolant leak or noise from the pulley area. Luckily, it’s a straightforward repair if caught early.

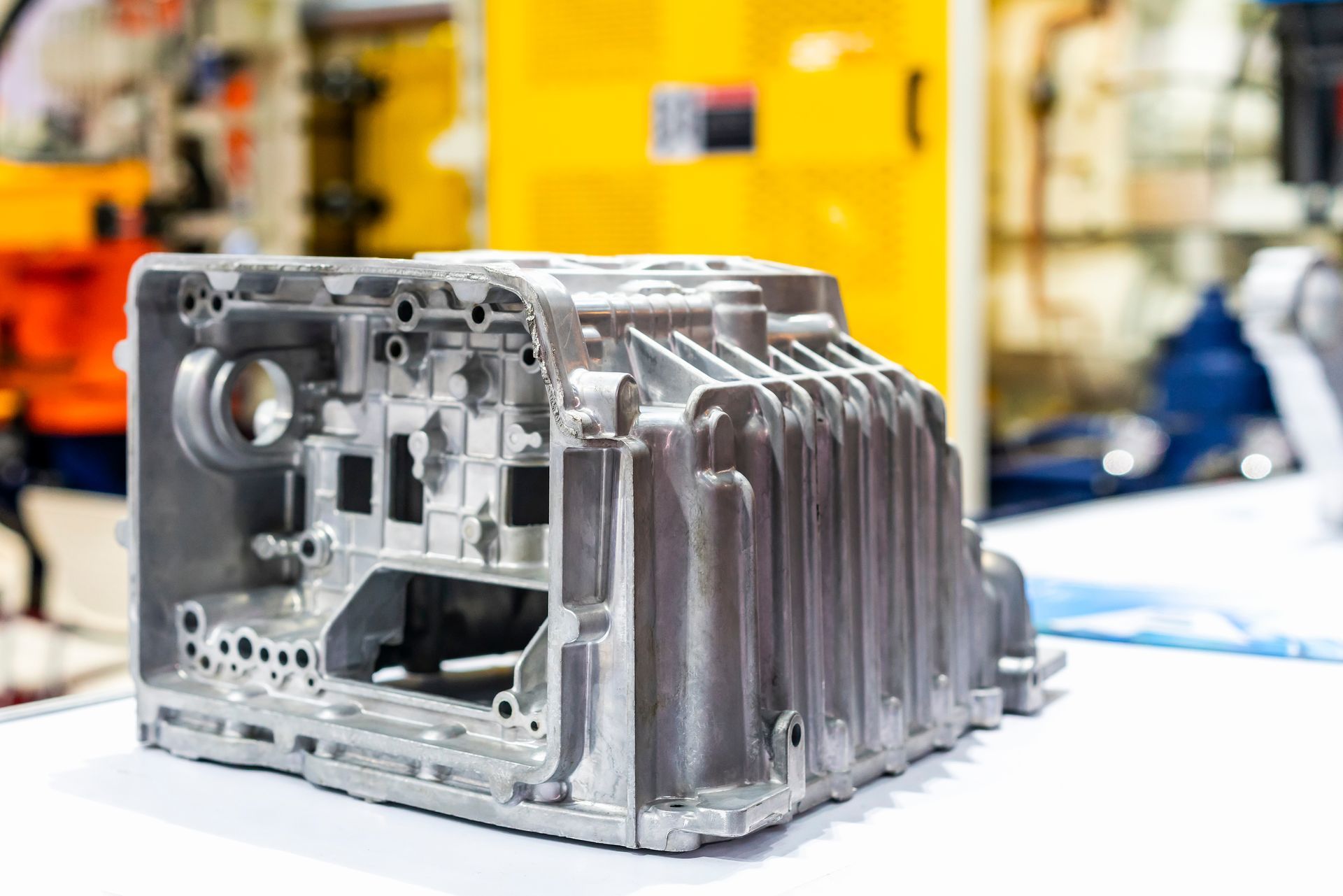

#53 Engine Block Cracks (Selective Years)

Some 1999–2001 engines have a “53” cast number on the block—these are known to be more prone to cracking. It’s a rare but serious issue, and something to keep an eye on if you own a truck from that era.

Common 6.7L Cummins Engine Problems

The 6.7L Cummins debuted in 2007.5 with added emissions technology and a few upgrades to meet modern regulations. It brought more torque, but also more complexity, which means a new list of common issues.

Emissions System Failures (EGR, DPF, DEF)

The 6.7 introduced Exhaust Gas Recirculation (EGR) and Diesel Particulate Filter (DPF) systems. These are the source of most performance and drivability complaints. Clogged DPFs, cracked EGR coolers, and stuck EGR valves are all common repairs, especially for trucks that see frequent short trips or lots of idling.

Turbocharger Failure

The 6.7’s Variable Geometry Turbo (VGT) helps with performance and towing but can stick due to soot buildup. Over time, this leads to poor boost, turbo noise, and eventually full failure. Cleaning or replacing the VGT is a familiar job on high-mileage 6.7s.

Fuel Injector and Oil Dilution Issues

Like the 5.9, the 6.7 uses high-pressure common-rail fuel injection. Worn injectors can cause poor fuel economy, hard starts, or white smoke. On top of that, fuel dilution in the engine oil—especially during repeated DPF regenerations—can thin the oil and accelerate engine wear.

Heater Grid Bolt Failures

Certain 6.7L models are known to drop intake heater grid bolts into the engine, causing catastrophic internal damage. This issue can often be prevented by inspecting or modifying the grid heater.

Transmission Wear

While not an engine problem, the 6.7’s torque can overpower factory automatic transmissions, especially the 68RFE. Transmission repairs or upgrades are common in tuned trucks or those used heavily for towing.

How the 5.9L and 6.7L Compare

Both engines have earned loyal followings, but they differ in key ways:

Design Simplicity vs. Technology

The 5.9 is simple, rugged, and easy to maintain. It has fewer electronics and no emissions systems. The 6.7 added displacement, a VGT turbo, and emissions hardware. While it delivers more torque and better efficiency, it also requires more attention to sensors and soot buildup.

Reliability

The 5.9 is often considered more reliable due to its mechanical nature and minimal emissions equipment. But the 6.7’s core engine is just as strong. The difference lies in the supporting systems—the 6.7 can be every bit as reliable if its EGR, DPF, and turbo systems are well maintained.

Common Repair Trends

For the 5.9, we often see injector replacements, timing cover reseals, and water pumps. On the 6.7, turbo swaps, DPF cleanings, and emissions sensor replacements are more common. Both engines can easily reach 300,000+ miles, but the 6.7 may need more attention along the way.

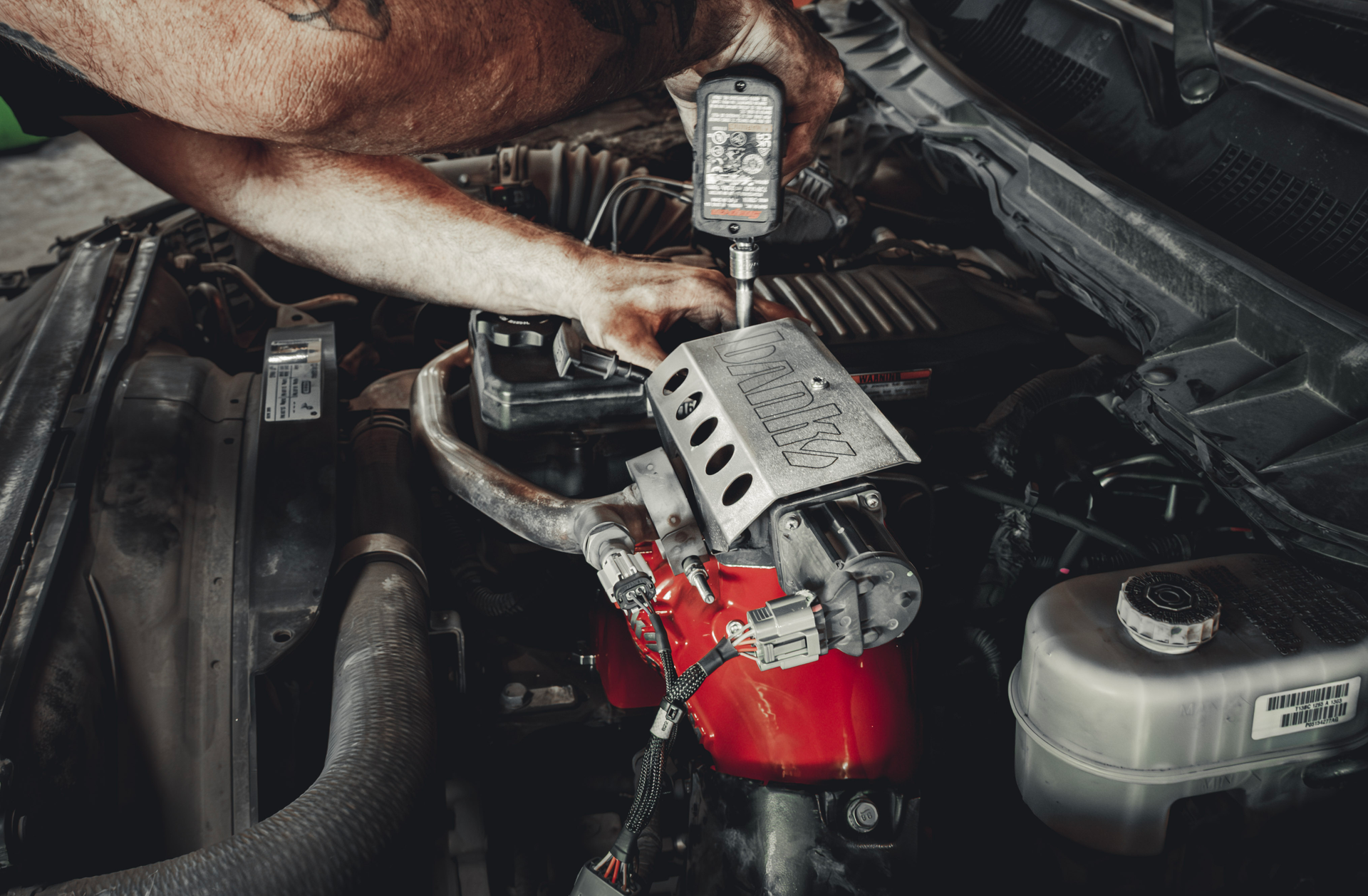

Deer Park Diesel – Cummins Experts in Clayton, WA

At Deer Park Diesel, we’ve worked on every generation of the Cummins engine. Whether you’re driving a no-frills 5.9L or a high-output 6.7L, we offer full-service diagnostics, repairs, and upgrades. From turbocharger replacements to fuel system diagnostics and everything in between, our team is ready to keep your diesel running strong.

Stop by or book your appointment today—we know Cummins engines inside and out.